Modern Welding 12th Edition PDF: A Comprehensive Article Plan

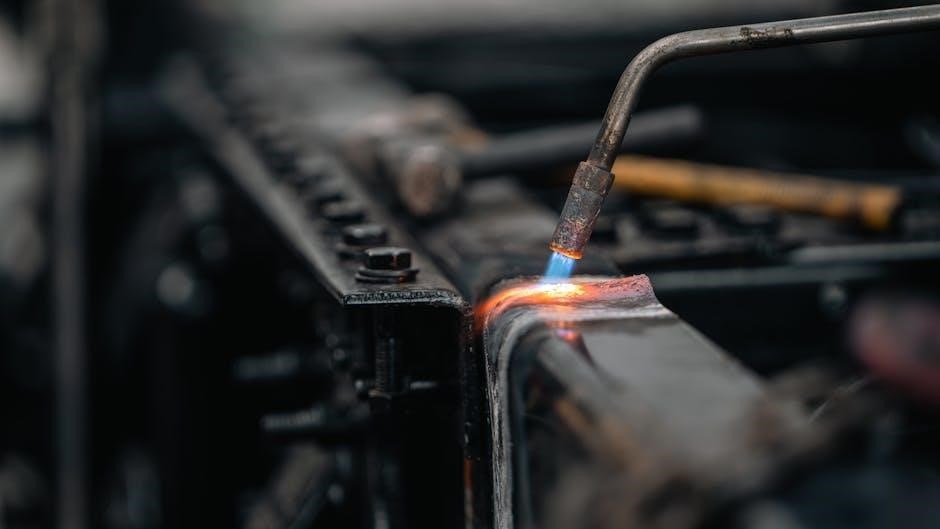

Modern Welding technology’s 12th edition‚ available as a PDF‚ delivers comprehensive coverage of arc welding‚ cutting‚ and related processes‚ enhancing skill development.

Modern Welding‚ now in its 12th edition‚ stands as a cornerstone resource for both aspiring and seasoned welding professionals. This extensively revised edition builds upon decades of established expertise‚ offering a thorough exploration of the evolving landscape of welding technologies. The text meticulously details core processes like SMAW‚ GMAW‚ GTAW‚ and FCAW‚ alongside cutting-edge advancements such as laser‚ electron beam‚ and plasma arc welding.

Beyond process descriptions‚ the 12th edition emphasizes welding metallurgy‚ material science‚ safety protocols‚ and practical applications across diverse industries – automotive‚ aerospace‚ pipeline construction‚ and general manufacturing. Its availability as a PDF facilitates convenient access for students‚ educators‚ and professionals seeking a definitive guide to modern welding practices. The book’s enduring relevance stems from its commitment to clarity‚ accuracy‚ and real-world applicability.

The Significance of the 12th Edition

The 12th edition of Modern Welding represents a crucial update to the field‚ reflecting significant advancements in welding technology and industry standards. This edition doesn’t merely reiterate established practices; it incorporates new materials‚ techniques‚ and safety regulations vital for contemporary welders. The PDF format ensures accessibility to the latest information‚ overcoming geographical barriers and facilitating continuous learning.

Furthermore‚ the updated content addresses the growing demand for skilled welders in sectors like aerospace and automotive‚ where precision and reliability are paramount. The inclusion of advanced welding processes – LBW‚ EBW‚ and SAW – prepares professionals for the challenges of modern fabrication. By embracing these innovations‚ the 12th edition solidifies its position as the definitive resource for mastering the art and science of welding.

Availability and Accessing the PDF

Obtaining the Modern Welding 12th Edition PDF requires exploring several avenues. While direct downloads from the publisher may necessitate a purchase or subscription‚ educational institutions often provide access to students enrolled in welding programs. Online retailers and digital libraries frequently list the PDF for sale or rent‚ offering convenient options for individual acquisition.

Caution is advised when sourcing from unofficial websites‚ as these may contain outdated or compromised files. Legitimate sources guarantee the integrity and completeness of the content. Consider checking academic databases and professional welding organizations for potential resources. Remember to verify the file’s authenticity before installation to safeguard your device and ensure access to the correct‚ updated edition.

Core Welding Processes Covered

Modern Welding details essential techniques like SMAW‚ GMAW‚ GTAW‚ and FCAW‚ providing in-depth knowledge of each process’s applications and practical implementation.

Shielded Metal Arc Welding (SMAW)

SMAW‚ commonly known as stick welding‚ remains a foundational process extensively covered in Modern Welding. The 12th edition provides detailed instruction on electrode selection‚ crucial for achieving desired weld properties across various materials. It thoroughly explains techniques for maintaining a stable arc‚ controlling weld pool geometry‚ and producing sound‚ high-quality welds in all positions – flat‚ horizontal‚ vertical‚ and overhead.

The text emphasizes proper joint preparation‚ including beveling and cleaning‚ to ensure adequate penetration and fusion. Furthermore‚ it addresses common defects encountered in SMAW‚ such as porosity‚ slag inclusions‚ and undercut‚ offering practical solutions for prevention and correction. Safety protocols specific to SMAW‚ including protection from fumes and arc radiation‚ are also highlighted‚ making it a complete resource for both beginners and experienced welders.

Gas Metal Arc Welding (GMAW)

Gas Metal Arc Welding (GMAW)‚ or MIG welding‚ receives substantial attention in the Modern Welding 12th edition. The resource details various transfer modes – short-circuit‚ globular‚ spray‚ and pulsed-spray – explaining their applications and optimal parameter settings. It provides in-depth guidance on selecting appropriate shielding gases‚ influencing arc characteristics and weld quality.

The text emphasizes the importance of wire feed speed‚ voltage‚ and travel speed control for consistent weld deposition. Troubleshooting common GMAW issues‚ like burn-back‚ porosity‚ and lack of fusion‚ is thoroughly addressed. Furthermore‚ the edition explores advanced GMAW techniques‚ including pulsed welding for improved control and reduced heat input‚ alongside safety considerations specific to gas-shielded welding environments.

Gas Tungsten Arc Welding (GTAW)

The Modern Welding 12th edition dedicates significant coverage to Gas Tungsten Arc Welding (GTAW)‚ also known as TIG welding. It meticulously explains the process‚ emphasizing the use of a non-consumable tungsten electrode to create a precise‚ high-quality weld. The text details various tungsten types‚ their characteristics‚ and appropriate applications for different materials.

Detailed instruction is provided on foot pedal control for amperage regulation‚ crucial for achieving desired weld bead profiles. Shielding gas selection – argon‚ helium‚ and mixtures – is thoroughly discussed‚ alongside techniques for back-purging to protect weld roots. The edition also covers common GTAW defects and their prevention‚ alongside advanced techniques like pulse GTAW for enhanced control and reduced distortion.

Flux-Cored Arc Welding (FCAW)

Modern Welding’s 12th edition provides extensive details on Flux-Cored Arc Welding (FCAW)‚ a versatile process suitable for various applications. The text differentiates between self-shielded and gas-shielded FCAW‚ outlining the advantages and disadvantages of each. It thoroughly explains the role of the flux core in providing shielding‚ deoxidation‚ and slag formation‚ contributing to weld quality.

The edition details electrode classifications‚ covering different flux types and their impact on mechanical properties. Parameters like voltage‚ amperage‚ and travel speed are discussed in relation to material thickness and joint design. Troubleshooting common FCAW issues‚ such as porosity and slag inclusions‚ is also addressed. Furthermore‚ the PDF edition illustrates techniques for out-of-position welding with FCAW‚ enhancing practical understanding.

Advanced Welding Technologies

Modern Welding’s 12th edition PDF explores cutting-edge techniques like laser‚ electron beam‚ plasma arc‚ and submerged arc welding‚ boosting efficiency.

Laser Beam Welding (LBW)

Laser Beam Welding (LBW)‚ detailed within the Modern Welding 12th Edition PDF‚ represents a highly focused and precise fusion process. Utilizing a concentrated laser beam‚ LBW achieves deep‚ narrow welds with minimal heat-affected zones. This technology is particularly suited for joining dissimilar metals and achieving high welding speeds.

The PDF edition thoroughly examines LBW’s advantages‚ including automation potential and the ability to weld in various environments. It also covers the intricacies of shielding gases‚ beam control‚ and material compatibility. Hybrid laser arc welding‚ explored in related research‚ aims to combine LBW’s precision with arc welding’s robustness for enhanced production reliability‚ as highlighted in cited studies.

Furthermore‚ the resource details safety considerations and quality control measures essential for successful LBW implementation‚ making it a valuable asset for professionals and students alike.

Electron Beam Welding (EBW)

Electron Beam Welding (EBW)‚ comprehensively covered in the Modern Welding 12th Edition PDF‚ utilizes a high-velocity stream of electrons in a vacuum to create fusion. This process delivers exceptionally deep‚ narrow welds with minimal distortion‚ making it ideal for critical applications demanding high integrity.

The PDF resource details EBW’s unique requirements‚ including vacuum chambers and specialized power supplies. It explores the advantages of precise control over the electron beam‚ enabling welds in a wide range of materials‚ including those difficult to join with conventional methods. Discussions include beam focusing‚ scanning techniques‚ and the impact of process parameters on weld quality.

Safety protocols related to high-voltage equipment and radiation shielding are also emphasized‚ alongside quality assurance procedures for ensuring reliable EBW performance‚ providing a complete understanding of this advanced technique.

Plasma Arc Welding (PAW)

Plasma Arc Welding (PAW)‚ thoroughly detailed within the Modern Welding 12th Edition PDF‚ employs a constricted arc—a plasma—to achieve highly focused and precise welds. This process excels in welding a diverse array of materials‚ including stainless steel‚ aluminum‚ and titanium‚ offering superior control and quality.

The PDF resource explains how PAW utilizes a nozzle to shape the plasma arc‚ concentrating its energy for deep penetration and narrow weld beads. It covers different plasma gas options‚ their impact on arc characteristics‚ and the advantages of both transferred and non-transferred arc modes.

Furthermore‚ the text highlights PAW’s suitability for automated welding systems and its ability to minimize heat-affected zones‚ alongside essential safety considerations and quality control methods for optimal results.

Submerged Arc Welding (SAW)

The Modern Welding 12th Edition PDF dedicates significant coverage to Submerged Arc Welding (SAW)‚ a process renowned for its high deposition rates and deep penetration. SAW utilizes a continuously fed consumable electrode and a blanket of granular flux‚ shielding the weld pool from atmospheric contamination.

The PDF resource details how the flux not only provides shielding but also contributes to weld metal properties and slag formation for protection during cooling. It explains various flux types‚ their chemical compositions‚ and their influence on mechanical characteristics.

Furthermore‚ the text explores SAW’s applications in heavy fabrication‚ such as shipbuilding and pressure vessel manufacturing‚ alongside discussions on automated systems‚ travel speeds‚ and troubleshooting common defects. Safety protocols related to flux handling are also emphasized.

Welding Metallurgy & Materials

Modern Welding’s 12th edition PDF thoroughly examines welding metallurgy‚ material properties‚ and their impact on weld quality and performance characteristics.

Understanding Welding Metallurgy

Modern Welding‚ 12th Edition‚ delves deeply into the complex science of welding metallurgy‚ crucial for achieving strong‚ reliable joints. The PDF resource meticulously explains phase transformations‚ solidification‚ and the formation of microstructures within the weld pool and heat-affected zone.

It details how different welding processes influence these metallurgical changes‚ impacting the final mechanical properties of the weldment. Understanding concepts like hardenability‚ grain growth‚ and residual stress is paramount. The text clarifies the role of alloying elements in controlling microstructure and enhancing weldability.

Furthermore‚ it explores the potential for defects – such as porosity‚ cracking‚ and inclusions – arising from improper metallurgical control‚ and how to mitigate them. This section provides a foundational understanding for selecting appropriate welding parameters and materials for specific applications.

Carbon Steel Welding

The Modern Welding 12th Edition PDF dedicates significant attention to carbon steel welding‚ the most prevalent application in many industries. It comprehensively covers the weldability of various carbon steel compositions‚ detailing preheating‚ interpass temperature control‚ and post-weld heat treatment techniques.

The resource explores suitable welding processes – SMAW‚ GMAW‚ FCAW‚ and SAW – for different carbon steel thicknesses and applications. It emphasizes the importance of electrode selection and shielding gas composition to prevent hydrogen-induced cracking and ensure adequate mechanical properties.

Detailed guidance is provided on controlling dilution‚ minimizing distortion‚ and achieving sound welds in carbon steel structures. The PDF also addresses common challenges like lamellar tearing and offers practical solutions for mitigating these risks‚ ensuring structural integrity.

Alloy Steel Welding

Modern Welding 12th Edition PDF provides in-depth coverage of alloy steel welding‚ acknowledging its increased complexity compared to carbon steel. It details how varying alloy compositions—like manganese‚ nickel‚ chromium‚ and molybdenum—impact weldability and necessitate specific techniques.

The resource emphasizes preheating requirements to prevent cracking‚ particularly in higher alloy steels‚ and discusses the importance of maintaining low hydrogen levels. It explores appropriate filler metal selection based on the base metal’s composition and desired weld properties.

Guidance is given on controlling the heat input to avoid grain growth and preserve toughness. The PDF also addresses post-weld heat treatment procedures to optimize mechanical characteristics and prevent embrittlement‚ crucial for high-strength alloy steel applications.

Stainless Steel Welding

The Modern Welding 12th Edition PDF dedicates significant attention to stainless steel welding‚ highlighting its unique challenges. It details the importance of preventing sensitization – chromium carbide precipitation – which reduces corrosion resistance. Proper filler metal selection‚ matching the base metal’s alloy content‚ is heavily emphasized.

The resource explains techniques like using low-heat input processes (GTAW‚ PAW) and employing post-weld heat treatments to maintain corrosion resistance. It covers the specific considerations for welding austenitic‚ ferritic‚ martensitic‚ and duplex stainless steels.

Furthermore‚ the PDF addresses the prevention of weld decay and pitting corrosion‚ common issues in stainless steel welds. It details cleaning procedures to remove scale and contaminants‚ ensuring optimal weld quality and long-term performance in corrosive environments.

Welding Safety & Best Practices

Modern Welding 12th Edition PDF prioritizes safety‚ detailing PPE‚ ventilation‚ gas handling‚ and electrical precautions for a secure welding environment.

Personal Protective Equipment (PPE)

Modern Welding‚ 12th Edition PDF‚ emphatically stresses the critical importance of Personal Protective Equipment (PPE) for welder safety. This includes specialized helmets with auto-darkening filters to shield eyes from intense radiation‚ protecting against arc flash and UV exposure.

Appropriate gloves‚ constructed from durable‚ heat-resistant materials‚ are essential to prevent burns. Flame-resistant clothing – jackets‚ pants‚ and aprons – safeguards skin from sparks and spatter.

Furthermore‚ the text highlights the necessity of safety glasses worn under the welding helmet for comprehensive eye protection during setup and cool-down. Proper footwear‚ typically leather boots‚ protects feet from falling objects and electrical hazards.

The PDF also details the importance of respiratory protection‚ particularly when welding materials that produce hazardous fumes‚ advocating for appropriate respirators and ventilation systems.

Ventilation and Fume Control

The Modern Welding 12th Edition PDF dedicates significant attention to Ventilation and Fume Control‚ recognizing welding fumes as a serious health hazard. It details how welding processes generate airborne contaminants – metal particles‚ gases‚ and dust – that can cause respiratory illnesses and other health problems.

The text emphasizes the hierarchy of controls‚ starting with process modification to reduce fume generation. Local exhaust ventilation (LEV) systems‚ positioned close to the welding arc‚ are presented as the primary method for capturing fumes at the source.

General ventilation‚ while less effective‚ is discussed as a supplementary measure. The PDF stresses the importance of proper airflow patterns and regular maintenance of ventilation equipment. It also covers the selection and use of appropriate respirators when ventilation is insufficient.

Safe Handling of Welding Gases

The Modern Welding 12th Edition PDF provides detailed guidance on the Safe Handling of Welding Gases‚ crucial for preventing accidents and ensuring a safe working environment. It covers the properties of commonly used gases – oxygen‚ acetylene‚ argon‚ helium‚ and carbon dioxide – highlighting their potential hazards.

The document emphasizes proper cylinder storage‚ including securing cylinders upright‚ away from heat sources‚ and in well-ventilated areas. It details procedures for connecting and disconnecting regulators‚ leak testing‚ and purging gas lines.

Furthermore‚ the PDF stresses the importance of using appropriate personal protective equipment (PPE) when handling gas cylinders and regulators. It also covers emergency procedures for gas leaks and fires‚ including proper shutdown protocols and evacuation plans.

Electrical Safety in Welding

Electrical Safety in Welding‚ as detailed in the Modern Welding 12th Edition PDF‚ is paramount due to the high voltages and currents involved. The resource thoroughly explains the risks of electric shock‚ burns‚ and arc flash‚ emphasizing preventative measures.

It stresses the necessity of using properly grounded welding equipment and ensuring all cables are in good condition‚ free from cracks or damage. The PDF outlines the importance of wearing dry‚ insulated gloves and clothing‚ and avoiding welding in damp or confined spaces.

Furthermore‚ it details lockout/tagout procedures for de-energizing equipment during maintenance and repair. The document also covers the proper use of ground clamps and the importance of avoiding contact with live electrical parts‚ promoting a culture of safety.

Applications of Modern Welding

Modern Welding’s 12th edition PDF showcases diverse applications‚ including automotive‚ aerospace‚ pipeline construction‚ and general manufacturing‚ utilizing advanced techniques.

Automotive Industry Welding

Modern Welding‚ 12th Edition‚ profoundly impacts the automotive sector‚ detailing techniques crucial for vehicle manufacturing. The PDF resource emphasizes resistance spot welding‚ a cornerstone for joining sheet metal components in car bodies‚ ensuring structural integrity and safety.

Furthermore‚ the text explores Gas Metal Arc Welding (GMAW) and laser beam welding (LBW) applications in chassis construction and exhaust systems. These processes deliver precision and efficiency‚ vital for high-volume production; The PDF also covers advanced high-strength steel welding‚ addressing the industry’s drive for lighter‚ more fuel-efficient vehicles.

Understanding metallurgy‚ as presented in the Modern Welding PDF‚ is paramount for achieving durable and reliable automotive welds‚ meeting stringent quality control standards.

Aerospace Welding Techniques

The Modern Welding 12th Edition PDF provides critical insights into the demanding welding requirements of the aerospace industry. It details the use of Gas Tungsten Arc Welding (GTAW) – also known as TIG welding – for its precision and high-quality welds on critical components like engine parts and airframe structures.

The resource emphasizes the importance of specialized alloys‚ including titanium and nickel-based superalloys‚ and the specific techniques needed for their successful joining. Electron Beam Welding (EBW) and Laser Beam Welding (LBW) are also covered‚ highlighting their ability to create deep‚ narrow welds with minimal distortion – essential for aerospace applications.

The PDF stresses non-destructive testing methods‚ like radiography and ultrasonic inspection‚ to guarantee weld integrity and safety in these high-stakes environments.

Pipeline Welding and Construction

The Modern Welding 12th Edition PDF dedicates significant attention to the specialized techniques used in pipeline welding and large-scale construction projects. It details the application of Shielded Metal Arc Welding (SMAW)‚ Gas Metal Arc Welding (GMAW)‚ and Flux-Cored Arc Welding (FCAW) for joining thick-walled pipes‚ often in challenging field conditions.

The resource emphasizes the importance of proper joint preparation‚ welding procedures‚ and quality control measures to ensure the structural integrity and long-term reliability of pipelines transporting oil‚ gas‚ and other vital resources. It covers multi-pass welding techniques and the use of specialized electrodes and shielding gases.

Furthermore‚ the PDF highlights the role of automated welding systems and remote monitoring technologies in enhancing efficiency and consistency in pipeline construction.

Manufacturing and Fabrication Welding

The Modern Welding 12th Edition PDF provides extensive coverage of welding processes integral to modern manufacturing and fabrication. It details how techniques like Gas Tungsten Arc Welding (GTAW) are utilized for precision work on thin materials‚ while Gas Metal Arc Welding (GMAW) and Flux-Cored Arc Welding (FCAW) are employed for higher-volume production.

The resource explores robotic welding applications‚ emphasizing automation’s role in increasing efficiency and reducing defects in manufacturing settings. It also covers welding of various metals commonly used in fabrication‚ including carbon steel‚ alloy steel‚ and aluminum.

Detailed sections address joint design‚ welding symbols‚ and quality assurance protocols crucial for producing consistently high-quality fabricated components and assemblies.

Resources and Further Learning

PDF access complements online courses‚ certification programs (AWS‚ ASME)‚ and industry standards‚ bolstering knowledge gained from Modern Welding’s 12th edition.

Online Welding Courses

Numerous platforms offer online welding courses‚ perfectly complementing the detailed instruction found within the Modern Welding 12th Edition PDF. These courses range from introductory levels‚ ideal for beginners‚ to advanced specializations like robotic welding or pipeline techniques.

Look for courses that align with AWS (American Welding Society) standards‚ ensuring curriculum relevance and industry recognition. Platforms like Udemy‚ Coursera‚ and Lincoln Electric’s own online school provide structured learning paths‚ often including video demonstrations‚ quizzes‚ and downloadable resources.

Supplementing your PDF study with interactive online learning allows for practical skill development and a deeper understanding of the principles outlined in the textbook‚ preparing you for certification and real-world applications.

Welding Certification Programs

Achieving welding certification significantly enhances career prospects‚ and the Modern Welding 12th Edition PDF serves as excellent preparation. The American Welding Society (AWS) offers a wide range of certifications‚ from Certified Welder (CW) to more specialized credentials.

These programs validate your skills and knowledge to potential employers. Consider certifications relevant to your desired welding career path – SMAW‚ GMAW‚ GTAW‚ or FCAW. Local community colleges and vocational schools frequently host AWS certification testing centers.

Thoroughly studying the PDF’s content‚ coupled with hands-on practice‚ will greatly increase your chances of success. Certification demonstrates a commitment to quality and safety‚ making you a highly valuable asset in the welding industry.

Relevant Industry Standards (AWS‚ ASME)

Understanding and adhering to industry standards is crucial for any welding professional‚ and the Modern Welding 12th Edition PDF implicitly references these vital guidelines. The American Welding Society (AWS) develops codes and recommended practices for welding processes‚ materials‚ and qualifications.

The American Society of Mechanical Engineers (ASME) provides standards for boiler and pressure vessel construction‚ heavily reliant on sound welding practices. These standards ensure safety‚ reliability‚ and quality in welded structures.

Familiarizing yourself with AWS D1.1 (Structural Welding Code – Steel) and ASME Section IX (Welding and Brazing Qualifications) is highly recommended. The PDF provides a foundational understanding‚ but direct study of these standards is essential for professional application and compliance;

Accessing the “Modern Welding” 12th Edition PDF

Obtaining the Modern Welding 12th Edition PDF requires careful navigation. While direct‚ free downloads can be risky due to potential malware‚ legitimate avenues exist. Authorized textbook retailers often offer digital versions for purchase‚ ensuring a safe and legal copy.

Educational institutions frequently provide students with access through online learning platforms or library databases. Checking with your school or training provider is a good first step. Subscription-based engineering resource websites may also host the PDF as part of their library.

Be wary of unofficial sources; prioritize reputable vendors to guarantee a genuine and complete version of this valuable welding resource.