Learning Arabic in India offers a gateway to cultural richness, cognitive growth, and enhanced career prospects, making it a valuable skill in today’s interconnected world.

1.1. Significance of Learning Arabic in India

Learning Arabic in India holds immense significance, bridging cultural gaps and fostering understanding between diverse communities. It connects Indians to the rich heritage of Arab nations, historically linked through trade and education. Arabic proficiency enhances opportunities in diplomacy, international business, and Islamic studies, which are highly valued in India. Additionally, it strengthens cultural exchange and opens doors to scholarships and academic collaborations. With India’s growing ties to Gulf countries, mastering Arabic becomes a valuable asset for professionals and students alike, offering a competitive edge in global markets and fostering mutual respect and cooperation.

1.2. Benefits of Arabic Language Skills

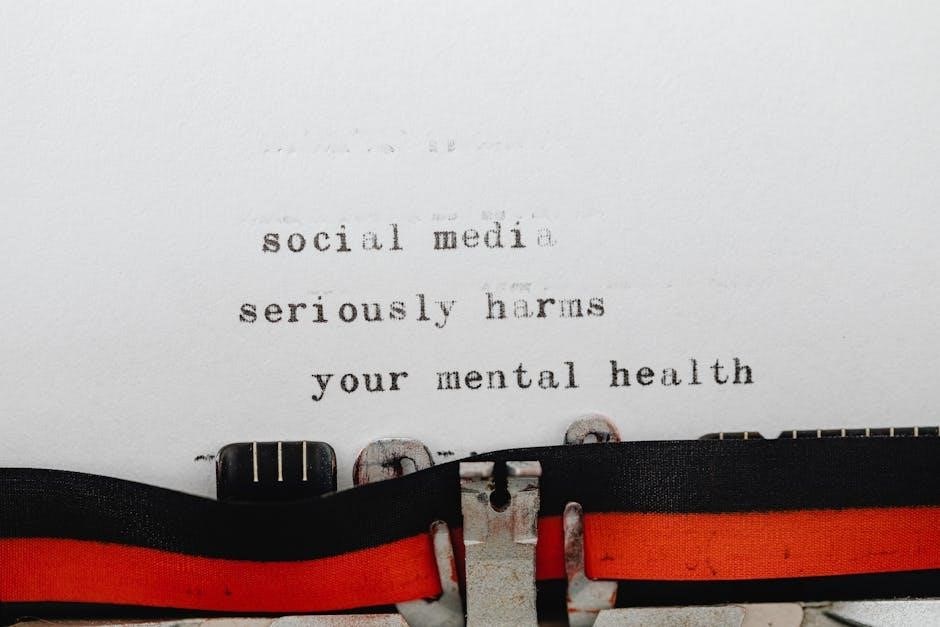

Acquiring Arabic language skills offers numerous benefits, including enhanced career opportunities in fields like diplomacy, international business, and education. It also fosters deeper cultural understanding and appreciation of Arab heritage. Arabic proficiency can improve cognitive abilities, such as memory and problem-solving, due to its complex structure. Additionally, it provides access to a vast library of Arabic literature, poetry, and religious texts, enriching personal and academic pursuits. In India, knowledge of Arabic can set individuals apart in competitive job markets, particularly in sectors with ties to Middle Eastern countries. Moreover, it strengthens communication skills and broadens perspectives, making it a valuable asset for personal and professional growth. Overall, learning Arabic is a rewarding endeavor that combines intellectual, cultural, and practical advantages, offering lifelong benefits for individuals in India and beyond.

1.3. Challenges of Learning Arabic in India

Learning Arabic in India presents unique challenges, primarily due to limited resources and cultural differences. One major obstacle is the scarcity of qualified Arabic teachers and structured learning programs outside urban centers. Additionally, the script and grammar of Arabic differ significantly from Indian languages, making it difficult for beginners to adapt. Cultural barriers also exist, as Arabic is deeply tied to Arab traditions, which may be unfamiliar to many Indians. Motivation can wane due to the perception that Arabic is less practically useful in India compared to other foreign languages; Furthermore, access to quality study materials and interactive learning tools is often restricted. These challenges highlight the need for dedicated support, resources, and community engagement to facilitate effective Arabic learning in India.

Why Learn Arabic?

Learning Arabic bridges cultural gaps, enhances career opportunities, and unlocks access to rich literary and religious texts, offering a rewarding journey of personal and intellectual growth.

2.1. Cultural Enrichment and Understanding

Learning Arabic provides a profound connection to the rich cultural heritage of the Arab world, including its history, literature, and traditions. By mastering the language, learners gain insights into the shared values and customs of Arab societies, fostering cross-cultural understanding. Arabic literature, renowned for its poetry and philosophical works, offers a window into the intellectual and artistic achievements of the region. Additionally, understanding Arabic enables learners to appreciate the cultural nuances embedded in Islamic studies, as the Quran and Hadith are written in Arabic. This cultural enrichment not only deepens personal knowledge but also promotes mutual respect and collaboration between diverse communities. For learners in India, studying Arabic bridges cultural gaps and enhances their ability to engage with Arab-speaking communities both locally and globally.

2.2. Career Opportunities in India and Abroad

Proficiency in Arabic opens up a wide range of career opportunities in India and internationally. With the growing ties between India and Arab countries in trade, diplomacy, and education, the demand for Arabic-speaking professionals is rising. Careers in diplomacy, international relations, and foreign services are promising, as Arabic is a key language in global diplomacy. Additionally, industries like tourism, hospitality, and export-import benefit from Arabic language skills. In India, roles such as translators, interpreters, and Arabic language teachers are in demand. Abroad, opportunities in Gulf countries, particularly in sectors like oil and gas, education, and consulting, are abundant. Arabic proficiency also enhances prospects in journalism, research, and cultural organizations. By learning Arabic, individuals gain a competitive edge in a globalized job market, making it a valuable skill for career advancement and professional growth.

2.3. Educational Advantages

Learning Arabic provides significant educational advantages, particularly for students in India. It opens doors to a wealth of Arabic literature, historical texts, and scholarly works, enhancing academic and intellectual growth. Arabic is the language of Islamic studies, making it essential for students pursuing degrees in theology, comparative religion, or Middle Eastern history. Additionally, knowledge of Arabic can broaden perspectives in fields like law, international relations, and cultural studies. Many universities in India and abroad offer scholarships and specialized programs for Arabic learners, creating opportunities for advanced study. Furthermore, bilingual and multilingual individuals often excel in competitive exams and academic competitions, giving them an edge in their educational journeys. By mastering Arabic, learners gain access to a rich cultural and intellectual heritage, enriching their educational experiences and fostering lifelong learning.

2.4. Personal Growth and Cognitive Benefits

Learning Arabic fosters personal growth by enhancing cultural understanding and broadening perspectives. It challenges the mind, improving cognitive abilities like memory, problem-solving, and multitasking. The complex script and grammar of Arabic sharpen mental agility, while the process of mastering a new language boosts confidence and resilience. Engaging with Arabic literature and poetry enriches emotional intelligence and empathy. Additionally, bilingual individuals often exhibit better executive control and delayed cognitive aging. The discipline required to learn Arabic cultivates patience and perseverance, valuable traits in all areas of life. Ultimately, acquiring Arabic is a transformative journey that enriches both the mind and spirit, offering a sense of accomplishment and opening new avenues for self-expression and personal fulfillment.

Getting Started with Arabic

Begin by mastering the Arabic alphabet, pronunciation, and basic phrases. Utilize textbooks, online courses, and language apps tailored for Indian learners. Consistent practice and engagement with the language will build confidence and a strong foundation for further learning.

3.1. Basic Steps to Begin Learning

Starting your Arabic learning journey in India begins with understanding the fundamentals. First, familiarize yourself with the Arabic alphabet, which is written from right to left. Practice the shapes, sounds, and pronunciation of each letter, as this forms the foundation of the language. Next, learn basic phrases and greetings, such as مرحبا (hello) and شكرا (thank you), to build confidence in speaking. Use textbooks or online resources designed for Indian learners, as they often align with local educational styles. Set clear, achievable goals, such as learning five new words daily or dedicating 30 minutes to practice. Engage with Arabic-speaking communities in India or online to gain practical exposure. Lastly, stay consistent and patient, as mastering Arabic requires time and dedication. These steps will provide a solid base for your learning journey.

3.2. Essential Resources for Beginners

For beginners in India, several resources are available to kickstart Arabic learning. Textbooks like Al-Kitaab and Arabic for Dummies provide structured lessons. Online platforms such as Duolingo, Arabicpod101, and YouTube channels like ArabicPod101 and Learn Arabic with Maha offer interactive learning. Apps like Memrise and Anki are excellent for vocabulary building. Local libraries and bookstores in India often carry Arabic learning materials tailored for Indian learners. Additionally, join online communities or forums where you can practice with native speakers. Engage with local Arabic-speaking communities or cultural centers in cities like Delhi or Mumbai for hands-on exposure. Lastly, utilize language learning apps and websites that cater to Indian learners, ensuring a smooth transition from familiar learning styles to Arabic. These resources provide a comprehensive starting point for your Arabic learning journey.

3.3. Setting Realistic Learning Goals

Setting realistic learning goals is crucial for effectively mastering Arabic. Start by defining clear, achievable objectives aligned with your motivation for learning the language. Break down larger goals into smaller, manageable tasks, such as dedicating 30 minutes daily to practice or mastering basic phrases within a week. Assess your current proficiency level and align your goals accordingly. For instance, if you’re a beginner, focus on learning the Arabic alphabet and basic grammar rules before moving to complex sentence structures. Establish both short-term and long-term milestones, celebrating progress along the way to stay motivated. Regularly review and adjust your goals to reflect your growth and evolving interests. Consistency and patience are key; set realistic timelines and prioritize quality over quantity in your learning journey.

Cultural Aspects of Learning Arabic

Learning Arabic in India bridges cultural gaps, offering insights into Arab traditions, Islamic heritage, and the rich literary history of the Middle East, enriching cross-cultural understanding and appreciation.

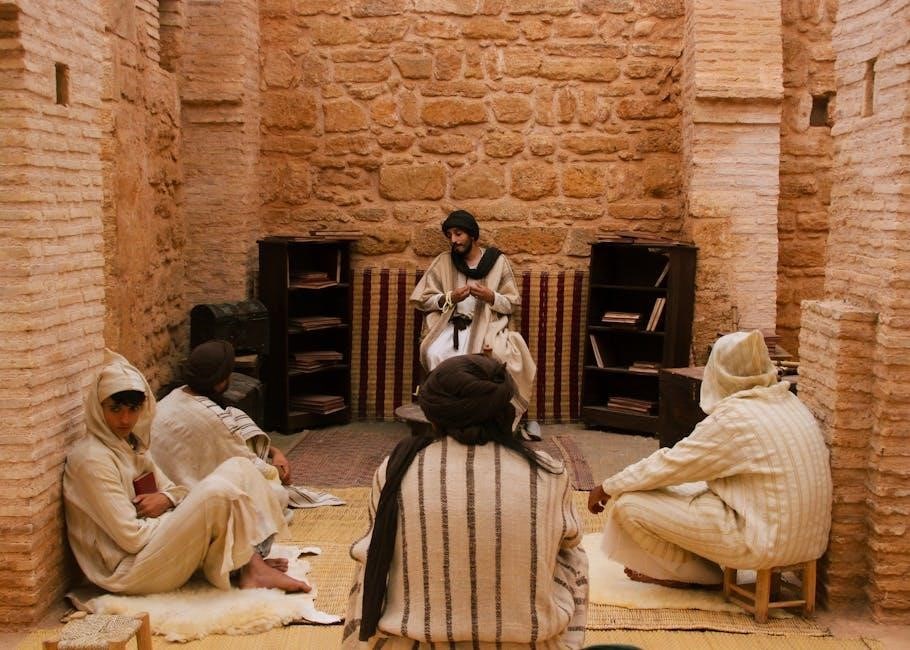

4.1. Understanding Arab Culture and Traditions

Understanding Arab culture and traditions is essential for learners of Arabic in India, as language and culture are deeply intertwined. Arabic is not just a means of communication but a window into the rich heritage of Arab societies. Learners gain insights into values like hospitality, respect, and family, which are central to Arab traditions. Islamic principles also play a significant role, shaping daily life and cultural practices. By exploring customs, festivals, and social etiquette, learners can better appreciate the cultural context of the language. This understanding enhances their ability to communicate effectively and fosters cross-cultural appreciation. Engaging with Arab culture also provides opportunities to connect with the vibrant traditions of Arab-speaking communities in India and globally.

4.2. The Role of Arabic in Islamic Studies

Arabic holds a profound significance in Islamic studies, as it is the language of the Holy Quran and the Hadiths, which are central to Islamic faith and practice. For learners in India, mastering Arabic enables a deeper understanding of Islamic texts, allowing for more accurate interpretation and spiritual connection. Many Islamic scholars and theologians in India emphasize the importance of Arabic for engaging with religious literature; However, challenges such as limited access to qualified teachers and resources can hinder progress. Despite these obstacles, the demand for Arabic learning in India is growing, particularly among Muslims seeking to strengthen their religious knowledge. By studying Arabic, learners can better appreciate the richness of Islamic heritage and contribute to theological discussions. This makes Arabic a vital tool for both religious and academic pursuits in India.

4.3. Engaging with the Arabic-Speaking Community in India

Engaging with the Arabic-speaking community in India is a valuable aspect of learning the language. India is home to a significant number of Arabic speakers, particularly in regions like Kerala, Gujarat, and Hyderabad. Interacting with native speakers and Arabic-speaking communities provides learners with opportunities to practice their language skills in real-life settings. Attend cultural events, join Arabic language clubs, or participate in community gatherings to immerse yourself in the language. Building connections with these communities not only enhances your learning experience but also fosters cross-cultural understanding. Additionally, many community members are eager to help learners improve their Arabic proficiency. By engaging with these networks, you can gain insights into cultural nuances and refine your language abilities in a supportive environment.

Practical Applications of Arabic

Mastering Arabic opens doors to practical applications in communication, cultural insights, and professional opportunities, enhancing your ability to connect with Arabic-speaking communities and utilize the language effectively in various fields.

5.1. Improving Speaking and Listening Skills

Improving speaking and listening skills in Arabic requires consistent practice and immersion. Start by listening to Arabic music, podcasts, and news to familiarize yourself with pronunciation and intonation. Practice speaking with native speakers or language partners through platforms like Tandem or HelloTalk. Use language learning apps like Duolingo or Babbel to engage in interactive exercises. Focus on mimicking native speakers’ accents and rhythms to enhance your pronunciation. Regularly record yourself speaking and compare it with native speech to identify areas for improvement. Dedicate time daily to converse in Arabic, even if it’s just for a few minutes. Surround yourself with the language as much as possible to build confidence and fluency in communication.

5.2. Mastering Arabic Writing and Reading

Mastering Arabic writing and reading is foundational for proficiency in the language. Begin by learning the Arabic alphabet, focusing on correct pronunciation and script. Practice writing letters, paying attention to their shapes and connections. Use worksheets or apps like Arabicpod101 to trace letters and improve handwriting; Dedicate time daily to read simple texts, such as children’s books or news headlines, to build familiarity with sentence structure. Listen to audio accompanying written content to enhance comprehension. Gradually progress to more complex materials like Quranic verses or classical literature. Consistent practice in writing short paragraphs and reading aloud will strengthen your skills. Immerse yourself in the written language by labeling objects at home with Arabic names and engaging in language exchange activities. Regular practice is key to fluency in reading and writing Arabic.

5.3. Using Arabic in Professional and Personal Life

Arabic language skills can significantly enhance both professional and personal life in India. Professionally, knowledge of Arabic opens doors in diplomacy, trade, and education sectors, especially with growing ties between India and Arab nations. In personal life, Arabic enriches cultural understanding and fosters connections with Arab communities in India. Learners can utilize Arabic in daily interactions, such as greeting Arab friends or engaging in cultural events. For professionals, it aids in business dealings, translation work, or interpreting. Additionally, Arabic proficiency can be applied in academia, research, and media. Personally, it allows deeper exploration of Arab literature, poetry, and Islamic studies. Incorporating Arabic into professional and personal life not only broadens opportunities but also enriches cultural and intellectual growth.

Advanced Learning and Specialization

Advanced Arabic learning involves exploring intricate grammar, classical texts, and specialized dialects, enabling learners to master literary works, dialectical variations, and field-specific terminology for expertise.

6.1. Diving into Arabic Literature and Poetry

Diving into Arabic literature and poetry offers a profound exploration of the language’s richness and cultural depth. From the timeless works of Al-Khansa to the philosophical verses of Al-Mutanabbi, Arabic poetry is a treasure trove of emotion, wit, and intellectual depth. Learners can immerse themselves in classical and modern texts, uncovering the unique literary devices, such as metaphor and simile, that define Arabic poetic traditions. Studying literature also enhances language proficiency, as it exposes learners to complex vocabulary and grammatical structures in context. Engaging with renowned authors like Naguib Mahfouz and Mahmoud Darwish provides insights into Arab history, society, and identity. This journey not only enriches linguistic skills but also fosters a deeper appreciation for the cultural and intellectual heritage of the Arab world. It is an essential step for those aiming to achieve mastery and connectivity with Arabic-speaking communities.

6.2. Exploring Dialects and Regional Variations

Arabic dialects and regional variations add layers of diversity to the language, reflecting the cultural and historical contexts of different Arab countries. Learners in India can benefit from exploring these dialects, such as Egyptian, Gulf, Levantine, and Maghrebi Arabic, each with unique pronunciation, vocabulary, and expressions. Understanding dialects enhances communication skills, especially in spoken Arabic, and provides insights into regional customs and traditions. While Modern Standard Arabic (MSA) is widely understood, dialects are essential for everyday conversations and connecting with native speakers. Resources like dialect-specific courses, regional media, and cultural exchanges can help learners navigate these variations. Mastering dialects not only broadens linguistic proficiency but also deepens cultural understanding, making learners more versatile and adaptable in Arabic-speaking environments.

6.3. Specialized Vocabulary for Specific Fields

Mastering specialized vocabulary in Arabic is crucial for learners aiming to excel in specific professional or academic fields. Whether it’s business, medicine, engineering, or Islamic studies, each domain requires tailored terminology. For instance, legal Arabic involves terms related to contracts and jurisprudence, while medical Arabic focuses on anatomical and pharmaceutical vocabulary. Learners in India can access field-specific textbooks, online courses, and glossaries to build expertise. Understanding these specialized terms not only enhances precision in communication but also opens doors to career opportunities in niche areas. Additionally, recognizing industry-specific jargon helps in navigating technical discussions and documents. By focusing on specialized vocabulary, learners can tailor their Arabic skills to meet the demands of their chosen field, ensuring practical application and professional growth.

Creating the India Learning Arabic Guide PDF

Developing a comprehensive guide simplifies Arabic learning, offering structured lessons, practical exercises, and cultural insights tailored for Indian learners, making it an invaluable resource for their language journey.

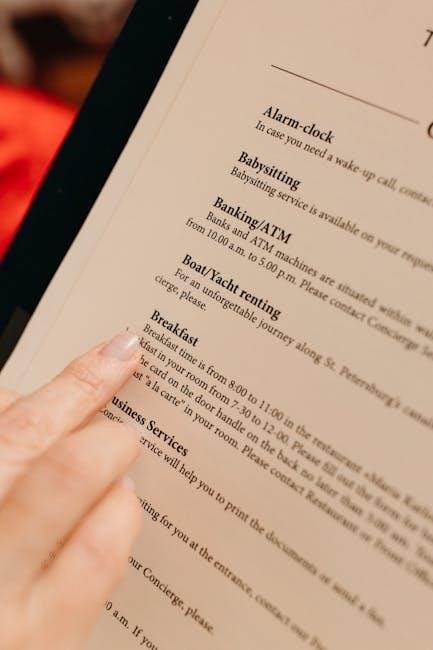

7.1. Structure and Content Overview

The India Learning Arabic Guide PDF is structured to provide a comprehensive yet accessible learning experience. It begins with foundational concepts, such as the Arabic alphabet, pronunciation, and basic grammar. The guide is divided into clear chapters, each focusing on specific skills like reading, writing, speaking, and listening. Cultural insights and practical applications are woven throughout to enhance understanding. Practical exercises, quizzes, and vocabulary lists are included to reinforce learning. The guide also incorporates visual aids, such as charts and diagrams, to simplify complex concepts. Additional resources, like answer keys and progress trackers, are provided to support self-paced learning. The content is tailored to cater to diverse learning styles, ensuring that learners at all proficiency levels can benefit. This structured approach makes the guide an invaluable tool for anyone aiming to master Arabic in India.

7.2. Including Practical Exercises and Quizzes

The India Learning Arabic Guide PDF integrates engaging practical exercises and quizzes to reinforce learning. These activities are designed to help learners apply their knowledge in real-world contexts. Exercises include interactive drills, fill-in-the-blanks, and sentence formation tasks, focusing on grammar, vocabulary, and pronunciation. Quizzes are varied, featuring multiple-choice questions, true/false statements, and matching exercises to test comprehension. Each chapter concludes with a quiz to assess understanding and identify areas for improvement. The guide also provides an answer key for self-assessment. These practical tools cater to diverse learning styles, ensuring active participation and retention. By incorporating these elements, the guide creates an interactive and effective learning experience, making Arabic accessible and enjoyable for learners in India.

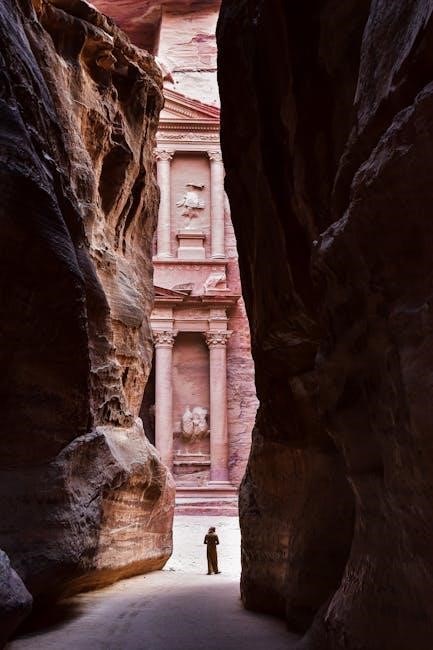

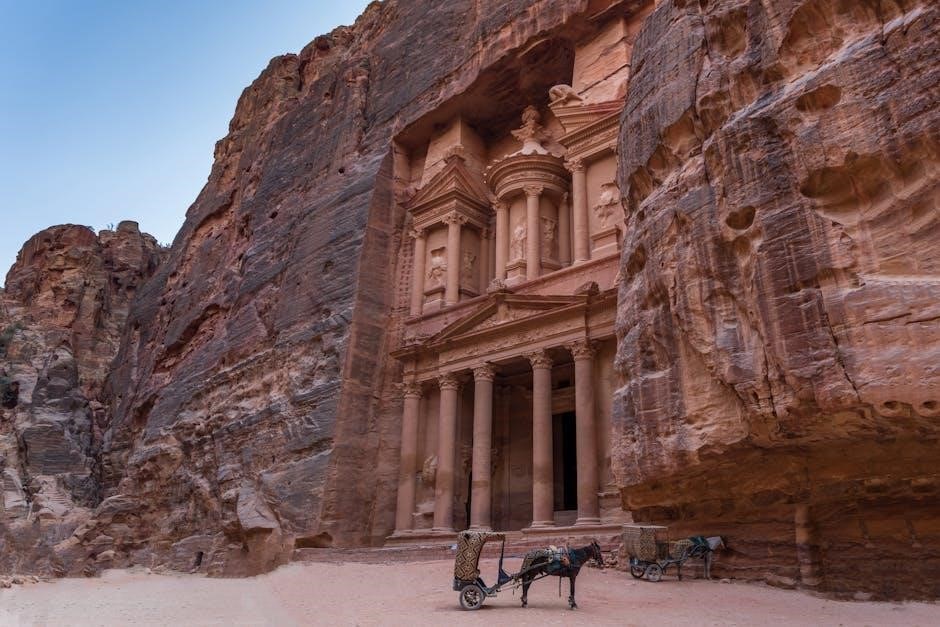

7.3. Adding Visual and Multimedia Elements

The India Learning Arabic Guide PDF enhances the learning experience by incorporating visual and multimedia elements. High-quality images, charts, and infographics illustrate complex concepts, such as Arabic script, grammar rules, and cultural nuances. Videos and audio clips provide authentic pronunciation models, enabling learners to mimic native speakers accurately. Interactive elements like clickable flashcards and quizzes make the guide engaging. Additionally, screenshots of language learning apps and online resources are included to guide learners in utilizing digital tools effectively. Cultural visuals, such as photos of historical sites and traditional attire, help learners connect with Arab heritage. These multimedia features create a dynamic and immersive learning environment, ensuring that learners in India can access a comprehensive and interactive Arabic learning experience.

Mastering Arabic is a rewarding endeavor, offering cultural, intellectual, and professional growth. This guide equips learners in India with tools to unlock Arabic’s potential, fostering a deeper understanding of its rich heritage and global significance.

8.1. Final Thoughts on Learning Arabic

Learning Arabic is a rewarding journey that opens doors to rich cultural understanding, intellectual growth, and diverse opportunities. It fosters a deeper appreciation for Arabic-speaking cultures, enhances cognitive abilities, and broadens career prospects. While the process may present challenges, perseverance and dedication yield lasting rewards. The ability to connect with millions worldwide through a shared language is invaluable. For learners in India, mastering Arabic not only bridges cultural gaps but also strengthens ties with the Arab world. Embrace this journey with curiosity and passion, leveraging resources and communities to stay motivated. Remember, language learning is a lifelong adventure, and every step forward is a step toward new discoveries and connections. Congratulations on taking the first step—keep exploring, learning, and growing with Arabic!

8.2. Next Steps and Continuous Learning

After laying a strong foundation, the next steps involve advancing your skills through consistent practice and immersive experiences. Engage with Arabic-speaking communities in India or online to enhance fluency. Explore advanced resources like Arabic literature, news, and media to deepen your understanding. Consider enrolling in specialized courses or seeking a tutor for personalized guidance. Regularly practice speaking and listening to refine your pronunciation and comprehension. Utilize language learning apps and tools designed for advanced learners. Reflect on your progress and adjust your learning strategies as needed. Continuous learning requires dedication, but the rewards of mastering Arabic are immense. Stay motivated by setting achievable goals and celebrating milestones. Embrace opportunities to use Arabic in professional and personal contexts, further solidifying your expertise. Remember, language learning is a lifelong journey—keep exploring, growing, and connecting through Arabic.